Revitalize Your Testing Machine

Don’t let an outdated or malfunctioning universal testing machine hold back your operations. An ADMET retrofit can transform your aging equipment into a high-performance asset. By integrating advanced components and controls, we breathe new life into worn-out tensile, compression, torsion, and bend testing systems.

Whether your machine is struggling to keep up with evolving material standards or a critical component has failed, a retrofit is often a more cost-effective solution than replacing it entirely. Many users unknowingly overlook this option, opting instead for a more expensive new system.

From simple upgrades like digital indicators for improved accuracy to complex overhauls featuring fully automated servo control and PC-based data acquisition, our retrofit services cater to a wide range of needs. We can modernize machines from top brands like Instron, SATEC, MTS, Tinius Olsen, Baldwin, and Forney.

Instron 4502 retrofitted with an ADMET MTESTQuattro Controller

Different Retrofits to Fit Your Needs

ADMET offers a number of different retrofit options to match your existing system and your testing requirements. Our experts will take the time to listen to your application requirements and make recommendations to ensure long-term success with your upgraded system. Read on to learn more about what options are available.

Data Acquisition Retrofits: A Fresh Start

Outdated dial gauges and underpowered digital indicators can hinder your testing accuracy and efficiency. ADMET’s data acquisition retrofits provide a powerful solution.

Single Channel Indicator Upgrade:

Our Pi Peak Load Indicator is the cornerstone of our data acquisition upgrades. By replacing your old indicator, you’ll enjoy:

- Effortless peak load and stress data analysis

- Elimination of manual data recording errors

- Greatly improved accuracy and repeatability

If your existing digital indicator can’t keep pace with evolving testing standards, it’s time for an upgrade. Our advanced indicators offer expanded calculation capabilities, ensuring your results meet the latest requirements.

Pi Peak Load Indicator

Multi-Channel Indicator Upgrade:

Take your testing to the next level with ADMET’s multi-channel indicator upgrade. By replacing your single-channel indicator, you can simultaneously measure force, displacement, and strain.

Our eP2 Digital Indicator is a prime example of this advanced technology. It generates precise stress-strain curves and calculates critical properties like offset yield, Young’s modulus, ultimate tensile strength, and percent elongation, all in accordance with ASTM E8 standards.

Leverage your existing extensometers and LVDTs to capture accurate displacement data and derive meaningful strain calculations. This upgrade empowers you to conduct more comprehensive material analysis.

eP2 Digital Indicator

PC-Based Data Acquisition Indicator Upgrade:

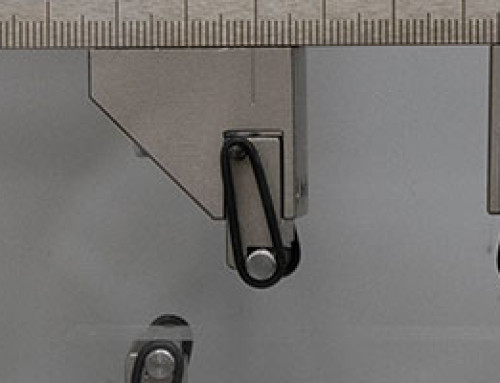

For the ultimate in testing flexibility and data analysis, consider our MTESTQuattro upgrade. This cutting-edge system combines powerful software with advanced hardware to transform your testing capabilities.

By installing a dedicated PC application and external interface box, you’ll gain access to a vast array of features beyond what standalone indicators can offer. Calculate complex material properties like plastic strain ratio (per ASTM E517) and K and n values (per ASTM E646) with ease.

MTESTQuattro excels in a wide range of tests including tension, compression, creep, fatigue, friction, flexural, relaxation, peel, and shear. The system’s base configuration provides essential channels for load, crosshead position, axial strain, transverse strain, and auxiliary inputs.

MTESTQuattro running on a connected PC

Transform Your Testing with Servo Control

Basic Electromechanical Servo Retrofit:

Upgrade your static or fatigue testing system to achieve new levels of precision and control with ADMET’s electromechanical servo retrofit.

By installing advanced servomotors, drives, and amplifiers, we can revitalize your machine’s performance to meet your exact requirements. In many cases, we can even integrate existing components, maximizing cost-efficiency.

Basic Hydraulic Servo Retrofit:

Maximize your existing hydraulic system with ADMET’s budget-friendly servo retrofit. By retaining your hydraulic unit and integrating a servo-manifold, we bypass manual control valves for precise, computer-controlled operation.

This upgrade provides full control over your testing system through our multi-channel digital controllers or powerful MTESTQuattro software. Experience the benefits of servo control without breaking the bank!

Comprehensive Hydraulic Servo Retrofit:

When your existing hydraulic unit is beyond repair, ADMET’s full servo retrofit provides a comprehensive solution. We’ll replace your old unit with a new servo hydraulic power unit, delivering optimal performance and reliability.

To control this advanced system, you can choose between our user-friendly multi-channel digital controllers or the robust MTESTQuattro software for advanced data analysis and test automation.

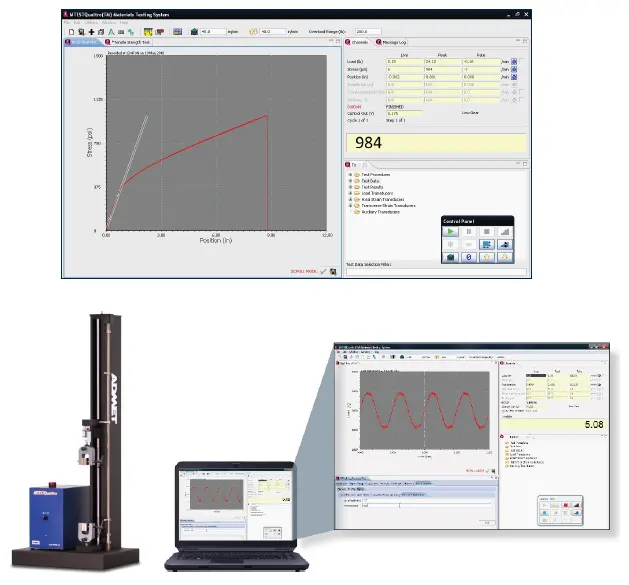

A 400,000 lb capacity manually operated Tinius Olsen Testing Machine retrofitted with ADMET’s MTESTQuattro® Materials Testing System. MTESTQuattro features load, position, axial strain, transverse strain and auxillary input channels

The Advantages of Retrofitting Your Universal Testing Machine

Cost-Effective Solution

Retrofitting your existing universal testing machine offers substantial cost savings compared to purchasing a new system. The load frame, often the most expensive component, remains intact while you upgrade essential elements like indicators and controllers. This strategic approach preserves your investment and extends the life of your equipment. Additionally, you can continue using your existing accessories, avoiding unnecessary expenses.

Enhanced Capabilities and Efficiency

A retrofit breathes new life into your testing system, expanding its capabilities and improving accuracy. You’ll benefit from increased flexibility in test types, faster testing cycles due to automated data capture and analysis, and the ability to generate comprehensive test reports effortlessly.

Compliance with Modern Standards

Older testing machines may struggle to meet current and evolving industry standards. ADMET’s retrofit solutions address this challenge by integrating advanced technology that ensures compliance with ASTM, ASME, AASHTO, ISO, and other standards. Our GaugeBuster 2 and DFG indicators are specifically designed for concrete testing, while MTESTQuattro and eP2 controllers offer a wide range of pre-programmed standards and customizable test procedures.

By choosing a retrofit, you’re not just upgrading your equipment; you’re optimizing your testing process for efficiency, accuracy, and future-proof performance.

Speak with a system retrofit expert today!

We’ll help you find the best path forward to meet your testing goals