Custom 400,000 lb Hydraulic Testing System for Gasket Testing

ADMET recently developed a custom-engineered solution for a client requiring a specialized hydraulic testing system to evaluate the performance of industrial gaskets. This Custom 400,000 lb Hydraulic Testing System was designed to conduct three specific tests critical to ensuring gasket reliability, highlighting ADMET’s expertise in tailoring machines to meet unique customer needs. At ADMET, our engineering team works closely with clients to design and build custom mechanical test equipment, from compact electromechanical systems to high-capacity hydraulic test frames like this one, ensuring your testing requirements are met with precision and efficiency.

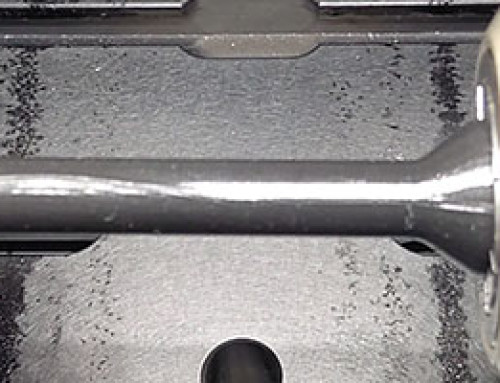

This robust hydraulic testing system, capable of compressing up to 400,000 lbs, was built to perform the following tests:

- Load Deflection Test (Set Load Hold): In this test, the gasket is compressed to a predefined load set point and held for a specified duration. After unloading, the recovered thickness of the gasket is measured using four high-precision linear displacement transducers, and the gasket is visually inspected for buckling or failure of spot welds. This test ensures the gasket can withstand sustained loads without permanent deformation or structural failure.

- Load Deflection Test (Load Verification at Specific Deflections): Here, the gasket is loaded and unloaded, and the operator checks the load at two specific deflection points to ensure it falls within predefined upper and lower limits. This test is critical for gaskets because it verifies their ability to maintain consistent sealing pressure under varying compression levels, ensuring they can handle dynamic operating conditions without over-compressing (which could lead to failure) or under-compressing (which could cause leaks).

- Hydrostatic Test: The gasket is compressed to a set load, then water is pumped and pressurized inside the loaded gasket, maintaining pressure for an extended period of time. A pressure drop or visible leakage indicates failure. This test simulates real-world conditions where gaskets must maintain a seal under pressure, ensuring reliability in applications like pipelines or pressure vessels.

Equipped with ADMET’s MTESTQuattro software, this custom hydraulic testing system generates detailed reports, force-displacement curves, and comprehensive data analysis for all three tests, providing valuable insights into gasket performance. The system’s four linear displacement transducers ensure accurate measurement of gasket deflection and thickness, delivering precise and repeatable results.

Ready to enhance your testing capabilities with a custom solution? Contact ADMET today to discover how we can design a testing system tailored to your specific application!

We'll custom engineer a system for you

Our engineers will listen to your needs and recommend the best solution to meet your goals