Material Testing Blog

How to Choose the Right Material Testing Machine for Your Needs?

Choosing the right material testing machine is crucial for any project. The right machine can enhance accuracy in testing. It can also improve reliability in results.

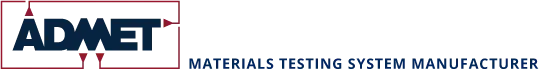

Consider the type of materials you will test. Will you work with metals, plastics, or other substances? Each material has unique properties. Not all machines can test every kind of material effectively. You may find some machines lack versatility. This limitation could impact your testing capabilities.

Evaluate your requirements carefully. Think about the scale of your testing operations. Will you need a machine for heavy-duty tasks or lighter applications? Identify your budget and long-term goals. Sometimes, a cheaper option might not serve your needs well. A poor choice can lead to complications. Always remember, the right material testing machine is an investment in your project's success.

Types of Material Testing Machines and Their Applications

When selecting the right material testing machine, it’s crucial to understand the types of machines available and their specific applications. For tensile testing, a tensile machine measures the strength and ductility of materials. This is vital in industries like construction and automotive. Compression machines test how materials resist crushing forces, used widely for concrete and metals.

Another type is a hardness tester. This machine determines the hardness of a material by measuring resistance to indentation. It is essential for industries dealing with metals and ceramics. Impact testers assess a material's toughness under sudden loads and are indispensable in the manufacturing of safety equipment.

Tips: Always assess your specific needs before choosing a machine. Different industries require different tests. Consider the material type as it directly affects the choice of machine. Visiting a facility to see machines in action can offer practical insights. Engaging with professionals in your industry may also illuminate common challenges or needs you might overlook.

How to Choose the Right Material Testing Machine for Your Needs?

| Type of Machine | Application | Load Capacity (kN) | Typical Test Standards | Key Features |

|---|---|---|---|---|

| Universal Testing Machine | Tensile, Compression, and Flexural Testing | 5 - 1000 | ASTM E8, ISO 6892 | Multi-functional, Easy to Operate |

| Hardness Tester | Hardness Testing of Materials | < 10 | ASTM E18, ISO 6508 | Portable, Fast Results |

| Impact Tester | Impact Resistance Testing | < 50 | ASTM E23, ISO 148 | Energy Measurement, User-Friendly |

| Fatigue Testing Machine | Cyclic Loading Testing | 1 - 100 | ASTM E467, ISO 1099 | High Precision, Long-Term Testing |

| Thermal Analysis Machine | Thermal Properties Testing | N/A | ASTM E2876, ISO 11357 | Accurate Temperature Control, Data Analysis |

Key Factors to Consider When Selecting a Testing Machine

Choosing the right material testing machine is essential for accurate results. There are several key factors to consider during the selection process. First, assess the type of materials you will test. Different machines serve various purposes. A tensile test requires different equipment than a hardness test. Understanding your material's properties is crucial.

Next, consider the capacity of the machine. Think about the maximum load it can handle. If your materials are heavy or dense, select a machine that meets those needs. Pay attention to the size of the test specimens too. Sometimes, a machine may not accommodate larger samples, leading to inaccurate results.

Finally, evaluate the ease of use. A complex machine may look impressive, but if it’s hard to operate, it can lead to errors. Training is essential but can be time-consuming. It should fit well within your workflow. Assess the software that comes with it too. Compatibility and user-friendliness can make a significant difference. Without these considerations, you may find yourself facing unexpected challenges during testing.

Material Testing Machine Selection Criteria

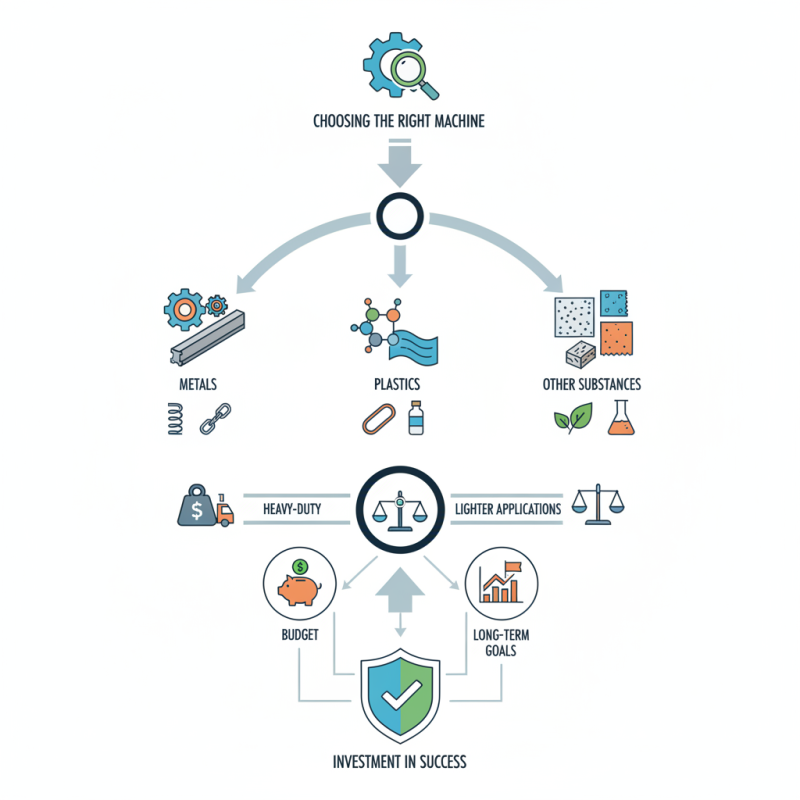

Understanding Material Properties and Testing Standards

Choosing the right material testing machine is vital for accurate assessments. Understanding material properties is the foundation of any testing process. Different materials exhibit distinct behaviors under stress. For instance, metals may bend, while plastics might break. Recognizing these traits is essential for selecting the appropriate testing standard.

Standards vary based on the type of material and the tests required. Mechanical properties, like tensile strength and hardness, often dictate the protocol. For example, a standard may specify how to prepare a sample and measure outcomes. However, sometimes these standards feel rigid or overly complex. Users may misinterpret them, leading to inaccurate results.

It's important to reflect on the limitations of available machines. Some may handle specific tests well but struggle with others. Selecting one machine for various tests can lead to compromise in precision. Open discussions within teams can bring diverse insights. Ultimately, understanding material properties and testing standards enhances decision-making in choosing a suitable machine.

Budget Considerations and Cost-Benefit Analysis for Testing Equipment

Choosing the right material testing machine involves careful financial planning. It's essential to evaluate your budget against the expected benefits. A recent industry report indicated that investments in high-quality testing machines can yield returns of up to 30% in enhanced product quality and reduced failures. Lower-priced machines often compromise on accuracy. Paying less frequently leads to higher long-term costs.

Conducting a cost-benefit analysis can help identify the most suitable machine. For instance, a machine priced at $50,000 might seem expensive. However, with an annual maintenance cost of 5% compared to a cheaper alternative with 15%, the better machine ultimately saves money. People often overlook this comparison, focusing only on the initial price rather than ongoing expenses.

Consider the specific testing requirements your projects demand. Many tests require precision. The right machine can significantly reduce waste materials and increase efficiency. A study found that 67% of companies reported lower operational costs after investing in state-of-the-art testing equipment. Yet, it’s crucial to assess whether those advanced features address your needs or simply add unnecessary complexity. Balancing budget constraints with the machine's capabilities ensures a more strategic investment.

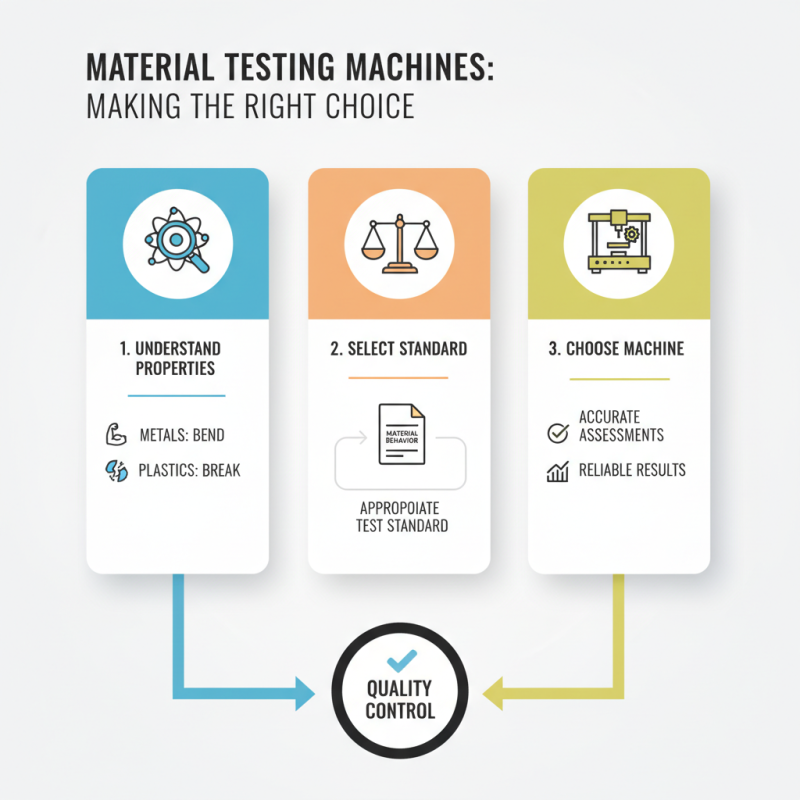

Maintenance and Support Services for Material Testing Machines

When investing in a material testing machine, maintenance and support services are crucial. Regular maintenance ensures that the equipment remains accurate and reliable. Dust, wear, and tear can accumulate, affecting performance over time. Scheduling routine checks is often overlooked. This can lead to unexpected breakdowns, delaying projects and increasing costs.

Support services should not be underestimated. Knowledgeable technicians can offer valuable insights during installation. They can also provide assistance for troubleshooting issues. Consider the availability of technical support when choosing a machine. It's frustrating to have equipment down while waiting for help. Additionally, clear documentation can aid in understanding machine operations and maintenance requirements.

Reflect on your specific needs. Not every testing machine requires the same level of maintenance. Some machines might need more frequent calibrations, while others are more robust. Evaluate your operational volume and the types of materials being tested. Finding the right balance between machine capability and maintenance demands is essential for productivity. Ultimately, making informed decisions regarding service and support will lead to a smoother testing process.