Material Testing Blog

How to Choose a Small Tensile Testing Machine for Your Needs?

In various industries, the demand for a small tensile testing machine is growing. According to a recent report by MarketsandMarkets, the global tensile testing machine market is expected to reach $1.2 billion by 2027. This increase highlights the importance of material testing in quality control and product development.

Choosing the right small tensile testing machine can be challenging. There are many factors to consider, such as load capacity, accuracy, and ease of use. Users often struggle with balancing these features to meet specific testing needs. Anecdotal evidence shows that improper selection can lead to inaccurate results, affecting product reliability.

Many manufacturers may overlook the importance of a small tensile testing machine. They may prioritize cost over quality, leading to suboptimal testing performance. This decision could result in costly product failures and safety concerns down the line. Investing in the right machine is crucial for maintaining quality and compliance in today’s competitive market.

Understanding the Basics of Tensile Testing Machines

Tensile testing machines are essential tools for material analysis. They determine how a material behaves under tension. Understanding their basic components aids in the selection process. For instance, a load cell measures the force applied to the specimen. This is crucial for accurate results.

Moreover, the software used plays a significant role. It processes the data collected during testing. Users often overlook the importance of user-friendly interfaces. Complicated software can lead to errors and misinterpretations. Thus, investing time in understanding these systems is beneficial.

Another factor to consider is the machine's capacity. This includes both the tensile strength of materials and the size of samples. A machine with a small capacity might not meet your needs. However, overspending on unnecessary features is not wise. Balancing your specific requirements with available options is a challenge. Reflect on these aspects to make a more informed decision.

How to Choose a Small Tensile Testing Machine for Your Needs? - Understanding the Basics of Tensile Testing Machines

| Dimension | Measurement Range | Accuracy | Load Capacity | Testing Speed | Power Supply |

|---|---|---|---|---|---|

| Max Length | 0-500 mm | ±0.5 mm | 1 kN | 5-500 mm/min | AC 220V |

| Max Width | 0-200 mm | ±0.2 mm | 0.5 kN | 1-1000 mm/min | AC 110V |

| Max Thickness | 0-20 mm | ±0.1 mm | 2 kN | 5-300 mm/min | AC 220V |

| Software Compatibility | Windows, MAC | ||||

| Additional Features | Data Acquisition, Graphing, Remote Access | ||||

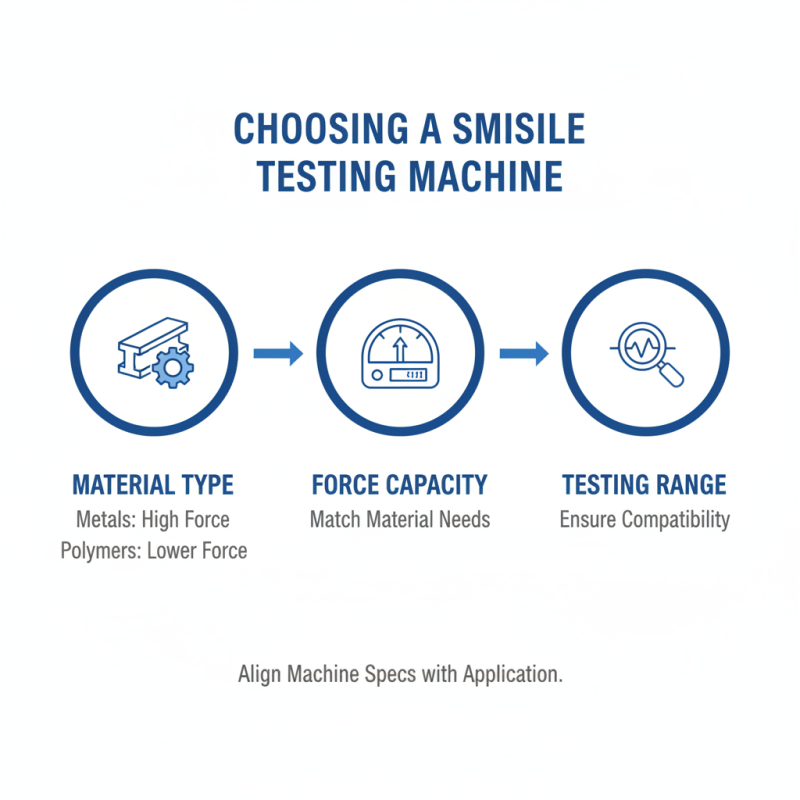

Key Factors to Consider When Choosing a Small Tensile Testing Machine

Choosing a small tensile testing machine requires careful consideration of several key factors. First, think about the materials you will test. Different materials require different testing ranges. If you deal with metals, you need a machine that can handle high forces. For polymers, a lower force capacity might suffice. It’s essential to match the machine’s capabilities with your material type.

Next, consider the machine’s ease of use. An intuitive interface can save time during testing. Look for features that simplify setup and operation. Calibration should be straightforward. A complicated machine can lead to errors. Think about how often you will use it. If it's for occasional tests, a simpler model may be enough. However, frequent testing might necessitate advanced features.

Lastly, check the data output options. A good machine should provide clear results. Data storage and export capabilities are vital for analysis. If you need consistency in testing, ensure the machine has reliable software integration. Reflect on your testing needs. Sometimes, what seems essential may not be necessary. Balancing all these factors will lead you to a suitable choice for your testing requirements.

Types of Small Tensile Testing Machines and Their Applications

When selecting a small tensile testing machine, consider the different types available. There are mechanical, hydraulic, and electromechanical options. Each type serves specific needs. Mechanical machines are often simpler and more cost-effective. They work well for straightforward material testing. Hydraulic machines can provide higher force levels but may require more maintenance. Electromechanical systems offer precise control, suitable for complex materials.

Applications vary widely. If testing textiles, a smaller, portable machine might suffice. For plastics, choose something with a higher load capacity. Some machines can handle multiple materials, but this can complicate the testing process. It's essential to assess your specific requirements. Think about the types of materials you will test. Will you need to run constant loads or variable ones?

While many machines boast advanced features, not all are necessary for basic testing. Sometimes, simpler systems can perform adequately. Reflect on how often you will use the machine. A feature-rich model might lead to unnecessary costs if you rarely need the extras. It’s a balance between features and practical use, ensuring you pick a machine that meets your needs without overspending.

Assessing Your Testing Requirements: Load Capacity and Features

When choosing a small tensile testing machine, understanding your testing requirements is crucial. Start by considering load capacity. What materials will you be testing? Polymers, metals, or composites? Each has specific strength characteristics. Ensure the machine can handle the maximum load you anticipate. A device with too low capacity may yield inaccurate results. Conversely, over-specifying can lead to unnecessary expenses.

Next, consider features. Digital displays, data logging, and user-friendly interfaces enhance functionality. Think about how you will use the machine. Will you require advanced features like stress-strain analysis? This could be beneficial for detailed research. However, simplicity might be your preference for routine testing. Also, evaluate the machine's size and portability. A compact design is ideal for limited spaces, but make sure it doesn’t compromise performance.

Reflect on your long-term needs, too. What projects will you undertake in the future? A more versatile machine may serve better as your requirements grow. Balancing features and capacity with your budget is vital. Don't rush this decision; it impacts your testing accuracy and efficiency significantly. Aim for a machine that aligns with both current and anticipated needs.

Budget Considerations for Purchasing a Small Tensile Testing Machine

When selecting a small tensile testing machine, budget plays a crucial role. According to industry reports, prices for these machines can vary significantly. Basic models can start at around $5,000, while advanced units may exceed $20,000. It's essential to define your requirements clearly. What materials will you test? What is your maximum load capacity? These questions will guide your budget.

Many buyers overlook additional costs. Calibration, maintenance, and software can add up. It’s important to consider long-term expenses, not just the initial purchase price. Investing in a more robust machine may save on future costs, but ensure it fits your operational budget.

Tips: Determine your testing frequency. If you test materials daily, a more durable model is wise. Also, check for warranty options. Some machines come with extensive support plans that can offset costs. Balancing budget against performance requires careful thought. Remember, cutting corners can lead to inadequate results. Always weigh the features against how they align with your needs.