Material Testing Blog

Top 5 Best Concrete Compression Machines for Optimal Performance?

In the world of construction, having the right tools is essential. Among these, the concrete compression machine stands out. Renowned industry expert Dr. Emily Hart emphasizes, "The precision of a concrete compression machine can make or break a project." Selecting the right model can influence the quality of the concrete used in structures.

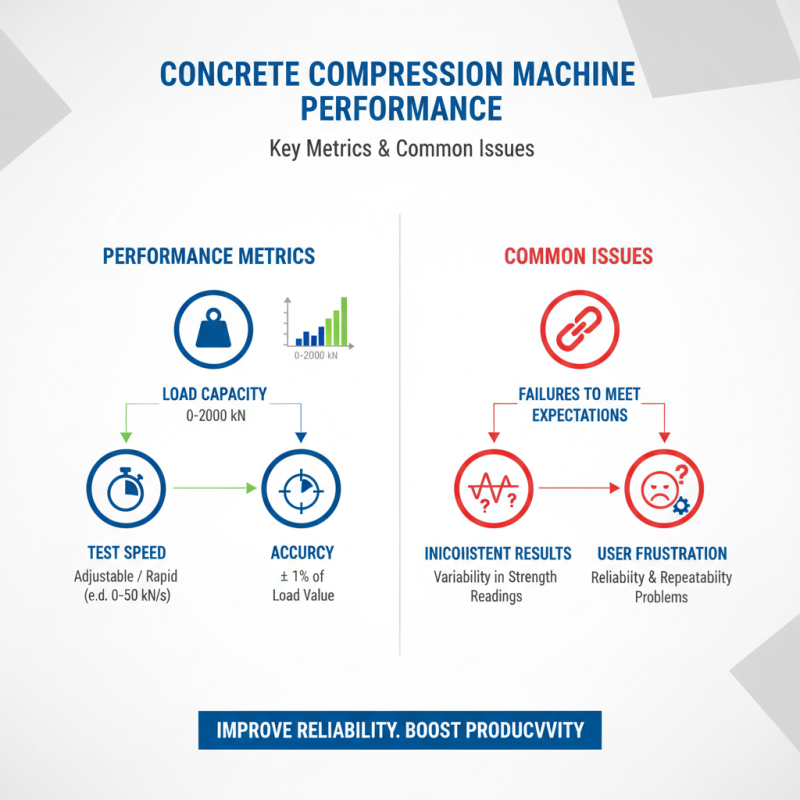

Many machines promise optimal performance, but how do we evaluate them? Features like load capacity, durability, and safety measures are crucial. However, users often overlook maintenance aspects. Neglecting these can lead to subpar results and costly repairs.

Understanding the market is key. The best machines offer reliability and efficiency. Yet, not every model suits every project. Professionals must assess their specific needs. A concrete compression machine should not only meet requirements but also adapt to various conditions. Choosing wisely can prevent unforeseen challenges.

Understanding Concrete Compression Machines and Their Importance

Concrete compression machines are vital in the construction industry. They test the strength of concrete by applying pressure until failure occurs. Understanding this equipment's role helps ensure construction safety and quality. Accurate testing aids in preventing structural failures, which can be catastrophic.

Industry reports indicate that concrete-related failures account for significant financial losses annually. According to a 2021 study, up to 20% of construction projects may suffer from compromised concrete quality. Effective use of compression testing machines can reduce these risks. It is essential to select the right machine for different concrete mixes and purposes.

Regular calibration and maintenance of these machines can significantly impact their performance. Some operators may overlook this, leading to inaccurate test results. Fine-tuning pressure settings and ensuring proper loading procedures are crucial. Continuous education on machine operation also enhances user confidence. It's not just about having the latest machine—understanding how to use it effectively is key.

Key Features to Look for in Concrete Compression Machines

When selecting a concrete compression machine, certain key features can significantly influence performance. A reliable machine should have a robust frame. This ensures durability and stability during testing. Additionally, the capacity of the machine matters. Look for models that can handle various sample sizes. This versatility adds value, especially for diverse projects.

Precision is another critical factor. Machines with digital readouts enhance accuracy. Ensure the equipment includes pressure control systems. Such systems maintain consistency throughout each test. Furthermore, the ease of use can make a difference. Intuitive interfaces help operators work efficiently. However, consider that not every machine is user-friendly. It’s important to test the interface before purchasing.

Lastly, think about maintenance requirements. Some machines demand frequent upkeep. This can affect long-term costs and performance. Research user experiences regarding maintenance issues. Reflecting on these aspects will guide you to a well-suited choice. Finding balance among features, usability, and maintenance can be challenging but essential for optimal results.

Top 5 Best Concrete Compression Machines for Optimal Performance

| Model | Max Load Capacity (kN) | Load Accuracy | Testing Standards | Dimensions (cm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 3000 | ±1% | ASTM C39 | 50 x 50 x 90 | 150 |

| Model B | 2500 | ±0.5% | ISO 7500-1 | 45 x 45 x 85 | 120 |

| Model C | 4000 | ±2% | EN 12390 | 60 x 60 x 95 | 180 |

| Model D | 1500 | ±1.5% | ASTM C109 | 40 x 40 x 80 | 100 |

| Model E | 3500 | ±2.5% | BS EN 12390-3 | 55 x 55 x 92 | 170 |

Top 5 Concrete Compression Machines Reviewed for Performance

When it comes to concrete testing, the right compression machine makes all the difference. These machines ensure accurate results for assessing the strength of concrete samples. For professionals, the quality of a compression machine can impact project outcomes significantly. Understanding the features of different models is crucial.

Selection should focus on ease of use, reliability, and calibration. Some machines excel at precision but may lack in user-friendliness. A machine that requires constant calibration can lead to frustration, affecting productivity. Check how these machines perform under varying load capacities, as this can reveal their limitations. It's important to find a balance between performance and practicality, ensuring they meet project needs without complications.

Efficient machines streamline the testing process but may come with a learning curve. Pay attention to the software integrations offered. Seamless data processing is valuable, yet some machines fall short in this area. An ideal machine not only meets immediate performance needs but also adapts to future challenges. Investing time in evaluating each option can reveal hidden flaws and refine the selection.

Performance Comparison of Top 5 Concrete Compression Machines

Comparison of Performance Metrics Among Leading Models

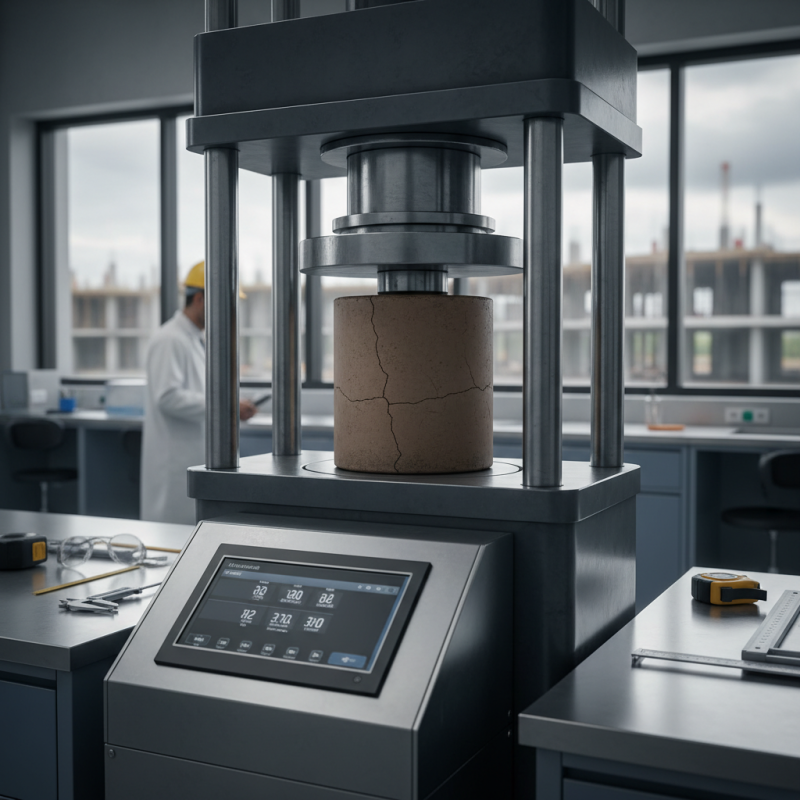

When it comes to concrete compression machines, performance metrics are crucial. Factors like load capacity, speed, and accuracy determine how well a machine performs. Many machines fail to meet performance expectations. Users often experience inconsistencies in results, which can lead to frustration.

A closer look at the leading models reveals varied results. Some excel in load capacity but lack speed. Others show a faster compression rate but fall short in precision. These discrepancies can impact project timelines and quality. User feedback often highlights the need for better calibration in certain models.

The materials used also play a pivotal role in performance. Machines with durable construction tend to perform better over time. However, some users noted wear and tear early in usage, necessitating frequent maintenance. Choosing the right machine requires careful consideration of these factors to ensure optimal performance.

Maintenance Tips for Ensuring Longevity of Compression Machines

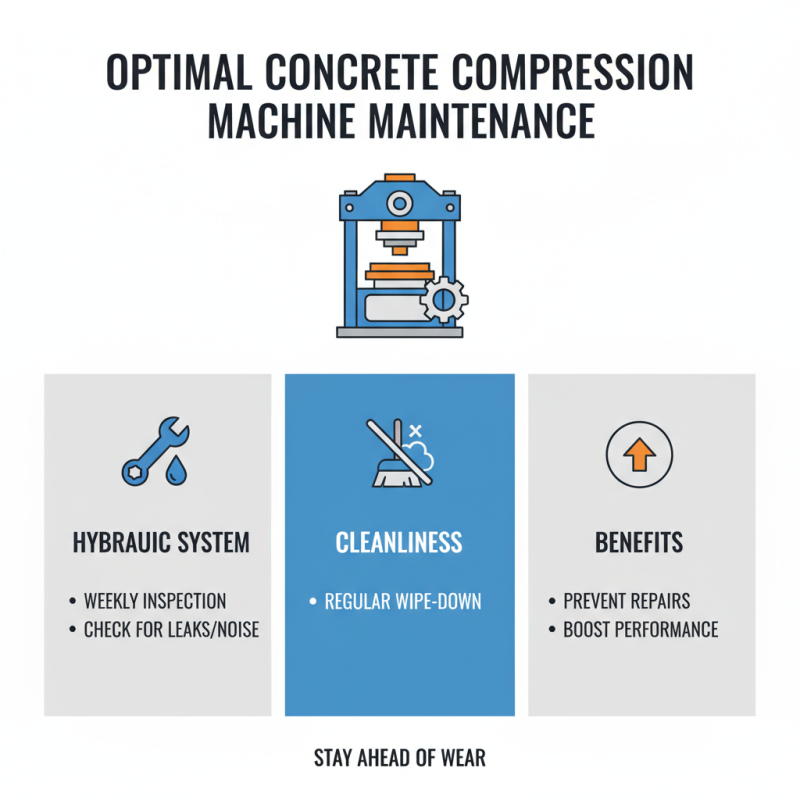

Maintaining concrete compression machines is essential for optimal performance. Regular checks can prevent costly repairs. Inspect the hydraulic system weekly. Look for leaks or unusual noises. These signs often indicate wear or failure. Keep the machine clean. Concrete dust can accumulate and lead to malfunctions. A simple wipe-down can go a long way.

Lubrication is a key aspect of maintenance. Machine parts need proper lubrication to function smoothly. Use the right type of oil to avoid damage. Consider the environment, too. Dusty or humid settings can affect lubrication frequency. Create a schedule for regular lubrication checks. This proactive measure helps extend the machine's lifespan.

Training staff on proper use is crucial. Misuse can lead to premature wear. Regularly review best practices with the team. Encourage feedback on machine performance. They may notice issues before they escalate. A culture of care and maintenance can significantly impact the machine's longevity. Remember, a well-maintained machine is more effective and efficient.